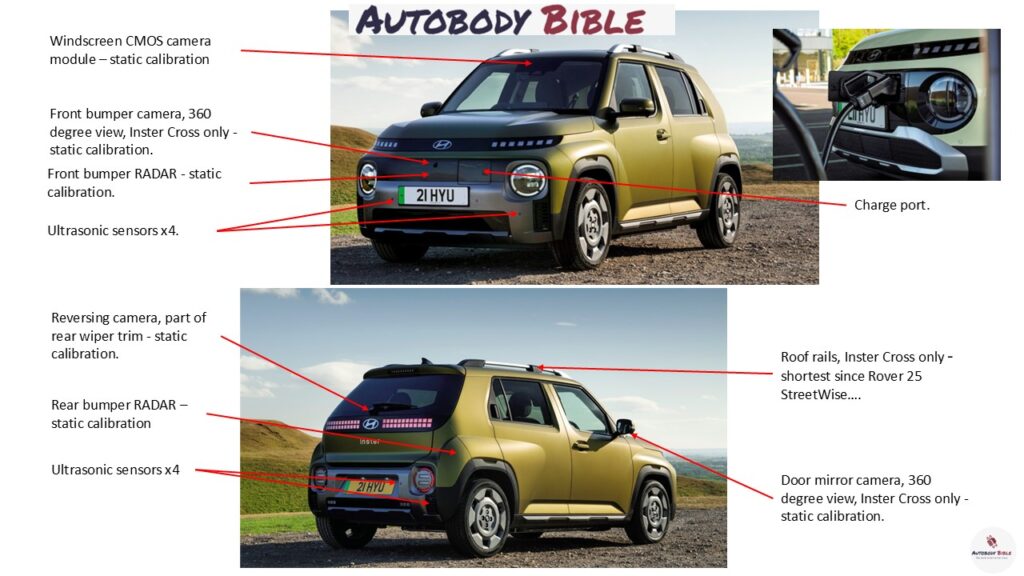

The Hyundai Inster AX1 EV might look like a city runabout, but under its compact skin lies a highly modern EV platform that demands serious consideration in the bodyshop. As EV adoption climbs across the UK and Europe, models like the Inster are poised to dominate urban mobility — bringing a new wave of repair challenges, calibration requirements, and battery handling concerns to shops used to simpler steel hatchbacks.

So, what do you need to know when this small EV rolls onto your shop floor? Let’s break it down.

1. Powertrain, Platform & Battery Tech

Though marketed as an affordable urban EV, the Inster shares major EV architecture components with larger Hyundai models like the Kona EV. That means what you’re seeing is not a dumbed-down electric car — it’s a compact shell wrapped around serious EV tech.

Key Technical Highlights:

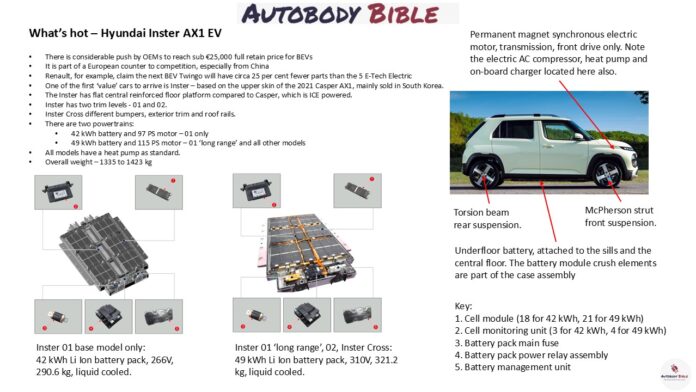

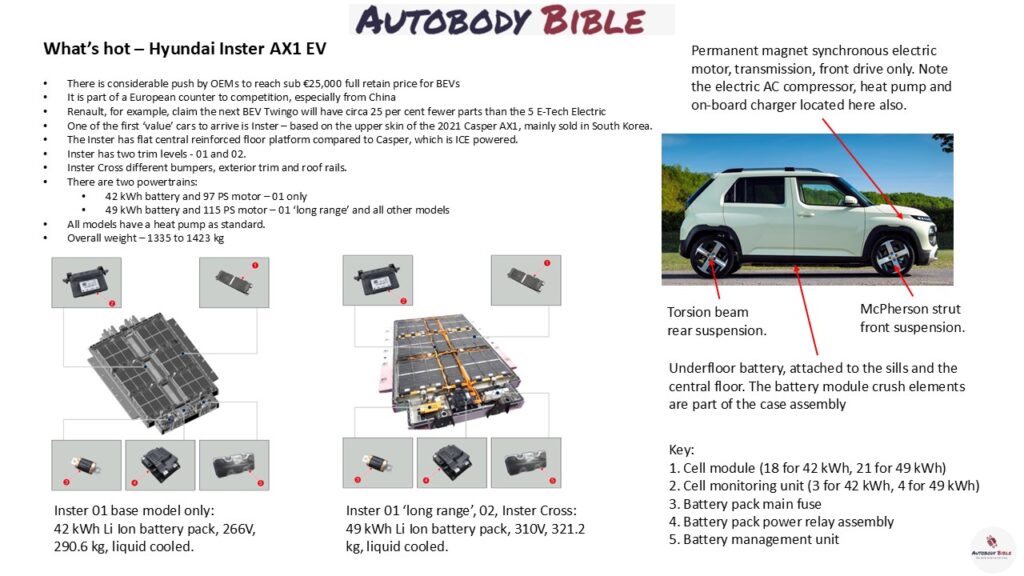

- Motor: Permanent magnet synchronous motor (PSM), front-wheel drive only

- Output: Up to 84.5 kW (113 hp), peak torque 147 Nm

- Battery Options:

- 42 kWh or 35.2 kWh LFP (Lithium Iron Phosphate)

- Supplied by HLI Green Power (joint venture between Hyundai and LG Energy Solution)

- Charging:

- Type 2 AC (up to 11 kW)

- CCS DC rapid charging

- Onboard charger rated at 11 kW

The LFP chemistry is noteworthy. It’s more stable and less prone to thermal runaway, which is great for safety — but adds weight. These packs are built into the underfloor crossmember structure, meaning they’re structurally integral and non-removable without major body disassembly. That’s a red flag for collision shops expecting quick underfloor swaps.

2. Suspension, Driveline, and Service Layout

Despite its EV underpinnings, the Inster retains a relatively conventional mechanical layout up front:

- Front Suspension: MacPherson strut

- Rear Suspension: Torsion beam (non-independent)

- Front-wheel drive only: No AWD version offered

This setup limits drivetrain complexity but also means that any front impact repairs may interfere with high-voltage cabling and motor mount points. Hyundai has kept access serviceable, but shops should train staff on safe disconnection procedures before doing anything near the motor or inverter.

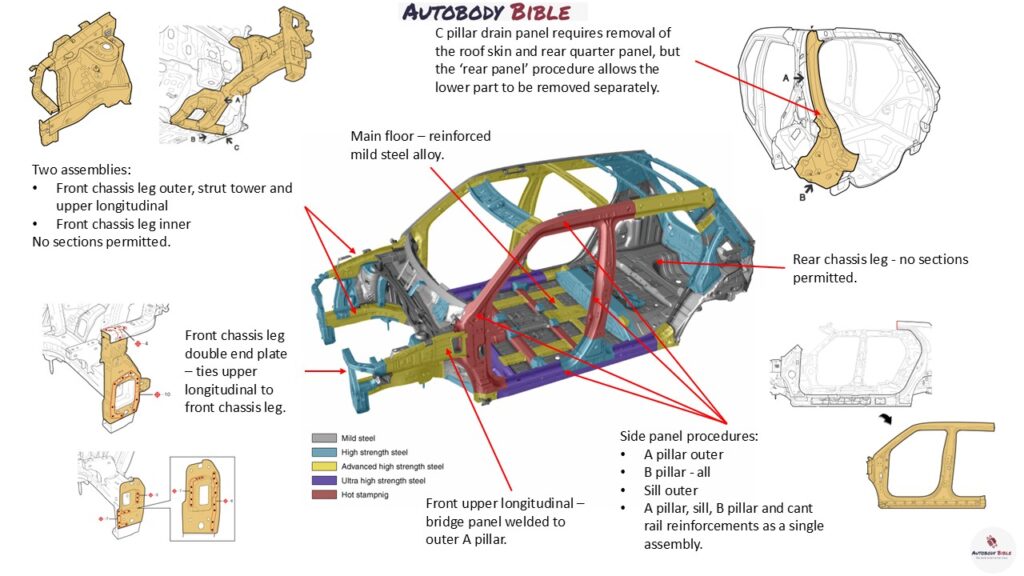

3. Body-in-White: No Cuts Allowed

Now for the repair-critical bit. The Inster’s body is deceptively complex. Its small footprint hides a heavily reinforced structure with extensive use of hot-stamped ultra-high-strength steel (UHSS) — particularly around:

- A-pillars

- Sills

- Front crash structure

- Battery floor supports

Key Structural Repair Notes:

- Front chassis legs come pre-assembled with upper strut towers and cannot be sectioned.

- Rear chassis legs: No sectioning permitted.

- Main floor: Reinforced multi-weld assembly – removal or repair requires complete module replacement.

- Side panel replacements include the full outer skin, A-pillar, B-pillar, and sill. Reinforcements must overlap with factory joints.

Shops that rely on quick segment repairs or aftermarket panel swaps will face a steep learning curve here. Structural bonding, laser welds, and high-strength steel behaviour during heat exposure must be carefully managed. This isn’t a £15,000 city car you can fix with a slide hammer and MIG torch.